General Discussion

Related: Editorials & Other Articles, Issue Forums, Alliance Forums, Region ForumsCalifornia's first 3D printer retail store to sell $600 model

We’ve all heard of 3D printers, but there still aren’t that many places where you can see, touch—and most importantly—try out a 3D printer before you commit to plunking down hundreds or thousands of dollars to add one to your own hacker den.

But if you find yourself in Southern California (specifically, Pasadena) on Sunday, you can attend the opening of Deezmaker, the West Coast’s first 3D printer retail store, set to open on September 23, 2012 at 2pm. That will bring the grand total of 3D printer retail stores in America (and possibly the world) to two.

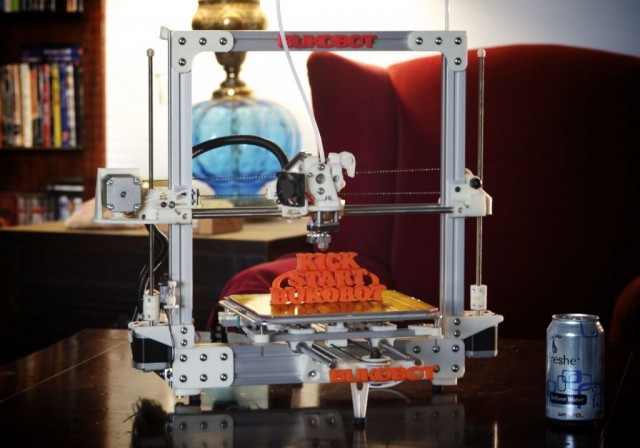

Bre Petttis’ MakerBot store in New York opened on September 20 to much fanfare in the maker and tech communities. That store sells MakerBot’s own Replicator 2 to the tune of $2,200. Meanwhile, Diego Porqueras’ store will sell his own recently Kickstarted "Bukobot" for just $600.

Various online 3D printer retailers have been around for some time, but these two stores are the first brick-and-mortar versions. Some 3D printing-related companies have already raised decent amounts of venture capital in recent months.

http://arstechnica.com/business/2012/09/californias-first-3d-printer-retail-store-to-sell-600-model/

Confusious

(8,317 posts)"Buko" reminds me of something else, something not polite.

DainBramaged

(39,191 posts)Jesus Christ on a popsicle stick, this is fucking AWESOME and you have a problem with the name?

Posteritatis

(18,807 posts)Confusious

(8,317 posts)It's suppose to be humorous.

I forget that some people here are humor impaired.

Confusious

(8,317 posts)It's suppose to be humorous.

I forget that some people here are humor impaired.

Posteritatis

(18,807 posts)Confusious

(8,317 posts)I don't care about the name.

Just making a joke that it reminded me of something else.

I forget some people here are humor impaired.

petronius

(26,602 posts)shock me if a machine already existed for that purpose)!

Extremely cool technology; I'm surprised it's available in any form as far down the price range as $600...

Confusious

(8,317 posts)I gotta get me one of those. ![]()

technology makes me ![]()

VenusRising

(11,252 posts)BUT I want one!!!!!

Those are amazing!

DollarBillHines

(1,922 posts)Retail signage, deluxe!

eShirl

(18,490 posts)mostly for creating miniatures, originally designed in 3DSmax for Second Life

a pjoning hook

custom beads for making jewelry

custom buttons (the sewn-on type)

rude cookie cutters

tinrobot

(10,893 posts)These little devices will evolve and grow quickly in features and power.

In a few years, you're going to see 3D printing do to manufacturing what digital music and video has done to entertainment. Many major players will fall, prices will drop, and companies will desperately try to control the intellectual property of the things they used to make, but are now being printed cheaply for the cost of materials and electricity.

Seriously thinking of buying one.

Jbradshaw120

(80 posts)And it make me wonder what will happen to all the jobs currently in manufacturing. I see it happening now in retail grocery with self checkouts and the new ideas floating around with smartphone product scanning. I see a future with high unemployment due to automation. Just a thought.

DainBramaged

(39,191 posts)new challenges, new opportunities

If it wasn't for the Republicans, half of our manufacturing base wouldn't be outside the country.

Confusious

(8,317 posts)If it prints metal, then I'll start to worry.

But the cool things is, you can probably print something in plastic, and then have it made of metal in a machine shop.

I think in the long run, it'll create more jobs then it kills.

eShirl

(18,490 posts)Mopar151

(9,978 posts)It was called stereolothography then. the company I worked for (TAFA) had a niche market for some of its metal spraying equipment - making sprayed metal molds from models. Stereolithography was being evaluated as a modelmaking process. Trouble is, you can't just make a mold of any shape - the model has to be shaped so that the mold sections will come off, i.e. tapered sides or sections of spheres, cylinders.... This is a pretty serious constraint, because incorporating this geometry into the model is anything but simple, and vexes those who want to be creative without learning the craft.

I've done a good bit of mold work in the context of machining, and have made a lot of complex stuff out of solid metal stock. If, absent hollow sections, you have enough geometric information to make something by 3D printing, you have enough to machine it from solid metal faster and more economically. The intermediate stage of making a plastic model is pretty much superflous. Computer numerical control of machine tools (CNC) is one of the first applications of computing to become comercially viable, and is still developing at a furious pace.

Confusious

(8,317 posts)I worked at a place that had a machine shop and did CNC work, so I know you can transfer the work from Solidworks to mastercam.

I guess the only thing I can think off would be to see how it looked and how it fit together first before you actually made it out of metal. Might be useful in some cases.

Mopar151

(9,978 posts)Edelbrock prototypes their intake manifolds that way now. You can make a pretty good foundry pattern with 3D, which is no small matter.

Look and feel is very useful - because you have to get approval from people who don't "get it" from a computer model (like Solidworks) or a shop drawing.

And I gotta say - if nobody's working on a way to make graphite EDM electrodes with 3D printing, they better get on it yesterday!

tinrobot

(10,893 posts)The metal printers cost more, but the technology is already there.

It's happening.

Confusious

(8,317 posts)And the metals are probably going to be pricy also.

And it also seems they're limited in types on metals.

So like I said, I'm not worrying about it.

I think the most annoying thing is the number of people who run around like chicken with their heads cut off talking about how things like this will "change the paradigm" or "democratize the masses" or "make capitalism obsolete" or "democratize capaitalism."

They were saying the same things 7 years ago, they'll be saying the same thing 70+ years from now.

Confusious

(8,317 posts)(and it can't) I find it doubtful.

Jbradshaw120

(80 posts)That puts some of my concern to rest.

Mopar151

(9,978 posts)but they are quite limited - most use stuff like zinc or aluminium powder.

eppur_se_muova

(36,258 posts)roguevalley

(40,656 posts)and they can make food. Sort of food. ![]()

DainBramaged

(39,191 posts)it cost TENS of THOUSANDS of dollars and hundreds of hours to turn a cad drawing into a prototype. Ten years ago we had the single core PIII to power the computers that powered the technology.

Look where we are today....

-..__...

(7,776 posts)Give it a few more years, and even the lower end models will be capable of this (as long as it isn't being sold at Harbor Freight)...

An American gunsmith has become the first person to construct and shoot a pistol partly made out of plastic, 3D-printed parts. The creator, user HaveBlue from the AR-15 forum, has reportedly fired 200 rounds with his part-plastic pistol without any sign of wear and tear.

HaveBlue’s custom creation is a .22-caliber pistol, formed from a 3D-printed AR-15 (M16) lower receiver, and a normal, commercial upper. In other words, the main body of the gun is plastic, while the chamber — where the bullets are actually struck — is solid metal.

The lower receiver was created using a fairly old school Stratasys 3D printer, using a normal plastic resin. HaveBlue estimates that it cost around $30 of resin to create the lower receiver, but “Makerbots and the other low cost printers exploding onto the market would bring the cost down to perhaps $10.” Commercial, off-the-shelf assault rifle lower receivers are a lot more expensive. If you want to print your own AR-15 lower receiver, HaveBlue has uploaded the schematic to Thingiverse.

HaveBlue tried to use the same lower receiver to make a full-blown .223 AR-15/M16 rifle, but it didn’t work. Funnily enough, he thinks the off-the-shelf parts are causing issues, rather than the 3D-printed part.

http://www.extremetech.com/extreme/133514-the-worlds-first-3d-printed-gun

The only downside... is the foreseeable potential for government interference/regulation/pressure that would force 3D printer manufacturers to embed recognition hardware/software that would defeat home built firearms hobbyists efforts.

hack89

(39,171 posts)The first ones will be very rudimentary but within a decade I bet you will be able to print a modern semi-automatic weapon.

This week, the so-called Wiki Weapon Project, an initiative that aims to design and build the world’s first entirely 3D-printable handgun, met its goal of raising $20,000 from Internet donors, according to the group’s spokesperson, University of Texas law student Cody Wilson.

The Wiki Weapon Project, hosted by a group that calls itself Defense Distributed, set out in July with the goal of raising enough money to hold a design competition among 3D-printable software models for a working gun capable of firing at least a single .22 caliber bullet that can be printed on a relatively cheap RepRap 3D printer.

http://www.forbes.com/sites/andygreenberg/2012/09/20/3d-printed-gun-project-hits-its-fundraising-goal-despite-being-booted-off-indiegogo/

Posteritatis

(18,807 posts)Not just on the firearms angle, though that's a wonderful way to kick up a moral panic about the things, especially given how completely ludicrous that pile of articles last month on the issue were.

I do sort of expect at least some blanket ban attempts on them on a mix of security and IP grounds. I doubt they'll necessarily be successful, but there haven't been many new technologies lately that haven't come with massive resistance.

Mopar151

(9,978 posts)Was to the toy industry, in countries with weak copyright laws. Once something has been successfully produced from a mold, it is relatively easy to spray a mold from it.

Skip Intro

(19,768 posts)Computer: Miller Lite, Cold.

NYC_SKP

(68,644 posts)We've got a little makerbot and a larger Stratasys Dimension 1200ES:

And I try to keep them, along with some laser cutters, running full time, but the raw stock for the Dimension is really expensive.

Our favorite new thing coming down the path is a cardboard cutting parts maker which can use free stock and let kids make parts quickly.

I LOVE this new line of rapid prototypers, thanks for the story, DB!

![]()

DainBramaged

(39,191 posts)eppur_se_muova

(36,258 posts)wait, maybe that wouldn't be a good idea ...

Bosonic

(3,746 posts)Last edited Sun Sep 23, 2012, 07:26 AM - Edit history (1)

RepRap Project

http://en.wikipedia.org/wiki/RepRap_Project

Not quite as swish as the retail models, but still...

http://vimeo.com/5202148#at=0

reformist2

(9,841 posts)GReedDiamond

(5,311 posts)...went down to the stripmall with the Deezmaker storefront, and went in to check it out.

I had some questions about the whole thing, such as, what kind of graphics program do I need to make the 3D art?

They had a table with food and beverages etc, and a bunch of these printers, on tables or shelves or whatever, around the perimeter of the space and in the middle of the (very small) room.

They are all a way lot smaller looking in person than they look on the internets tubes.

They also look like industrial design prototypes, not in any way the kind of thing you would see in a Staples, Office Depot or WalMart.

I think maybe four were actually in the process of printing out the two parts for what looked like some kind of chip-clip thing, though highly stylized.

They were being run from individual laptops, on which you could see the computer graphic being printed.

There was a guy in the corner, who, I think, was providing a musical background by manipulating a stylus or sumthin on a ipad type of thing, which was being projected on the wall next to him. It was a kind of indistinct form of electronic/random computer music, maybe. Not sure.

In any case, it seemed to me that the whole room was filled ONLY with the people who worked on the project, their immediate friends and families, and related hardcore technogeeks.

I left after less than five minutes, cuz I felt like some guy who just party-crashed some person's birthday party, with the "who the fuck are you?" vibe goin on.

I'll go back on another day and find out if it's worth getting one of these at this early point in its development.

All I can say is, these things may work perfectly well, but I think they need some kinda high-end product design Art Center type of "case" to make them marketable to the general public...maybe...I don't know?

They literally look like research projects or laboratory equipment.